Subway shield starting and reaction frame

Key words:

Ruilong

Classification:

Product Description

With the development of subway construction, shield construction method plays an increasingly important role in subway construction. Its superiority is actually due to the development of shield technology. In the process of shield tunnel construction, the excavation destroys the original stress state of the stratum, which will cause the movement of the stratum, and the result of the movement of the stratum will inevitably lead to different degrees of ground subsidence. When the differential settlement is too large, it may lead to the settlement or deformation of the surface.

Preliminary preparations for shield launching

In order to ensure the smooth starting of the shield machine, a series of preparations are required, mainly including: 1. end reinforcement; 2. portal cutting and ring plate installation; 3. installation and commissioning of ground-related supporting facilities; 4. installation of shield machine bracket and reaction frame; 5. track laying; 6. shield machine going down, assembly and commissioning, etc.

Before the shield is launched, the stability of the stratum at the entrance of the tunnel shall be evaluated and targeted treatment measures shall be taken. The end reinforcement generally adopts mixing pile, rotary spray pile, plain concrete continuous wall, freezing method, grouting method, SMW method, etc. Which method should be selected according to the specific formation conditions, and the whole process should be strictly controlled. The reinforced soil at the end must have good stability and waterproofness to ensure that the end body does not collapse or leak when the shield machine starts.

Before the excavation of the portal, plum blossom holes shall be drilled within the scope of the portal, with a depth of about 1.5~2.0m and a spacing of about 1m. The safety of the portal shall be identified by observing whether there is water seepage and sand leakage. If there is no obvious water leakage, the portal is cut and divided into blocks by manual cutting from top to bottom.

Ground-related supporting systems: ground systems mainly include muck, segment and other transportation systems, mixing station grouting system, battery car charging system, tunnel ventilation system, communication system, etc.

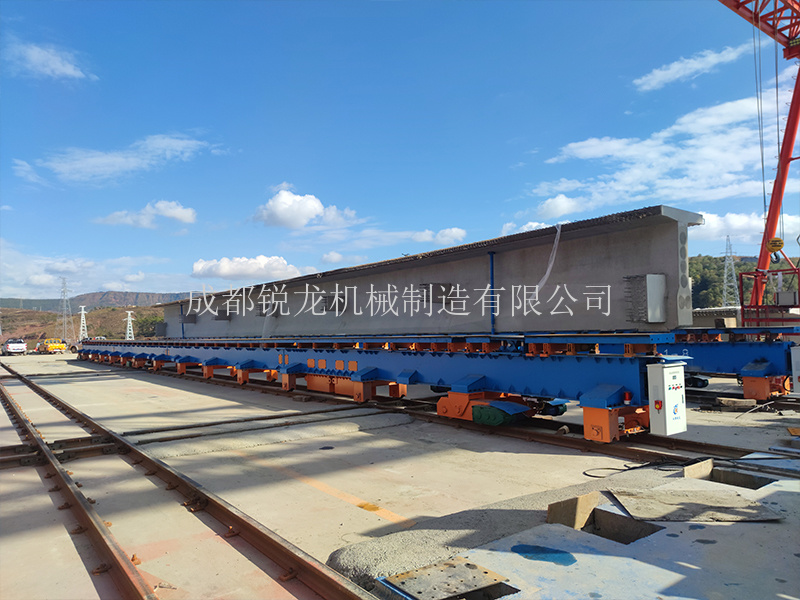

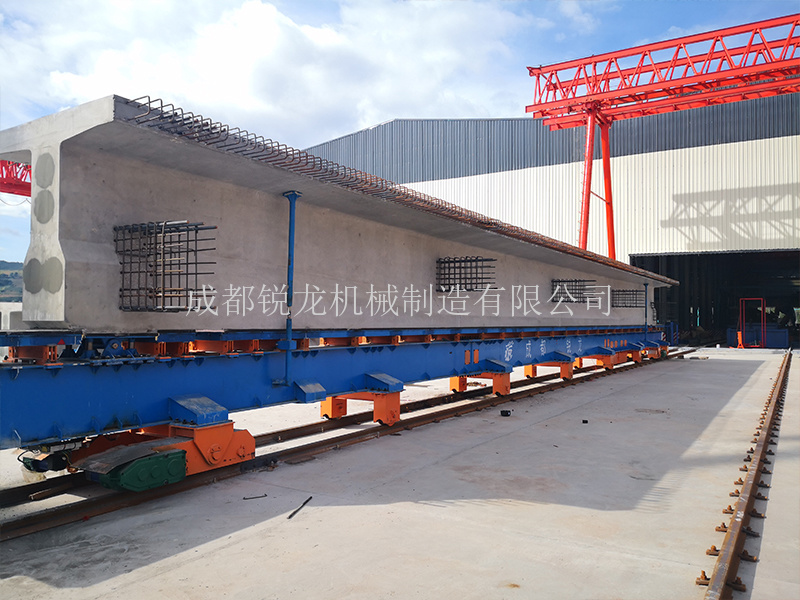

The shield machine for bracket installation shall be started at a certain slope. However, considering that the center of gravity of the shield machine is close to the front during the starting tunneling process, downward "kowtowing" phenomenon is easy to occur during the starting tunneling. The bracket elevation shall be 20~30mm higher than the design elevation. The bracket of the shield machine shall be set according to the planned posture of the shield machine and placed perpendicular to the portal direction. The bracket is made of section steel and assembled on site.

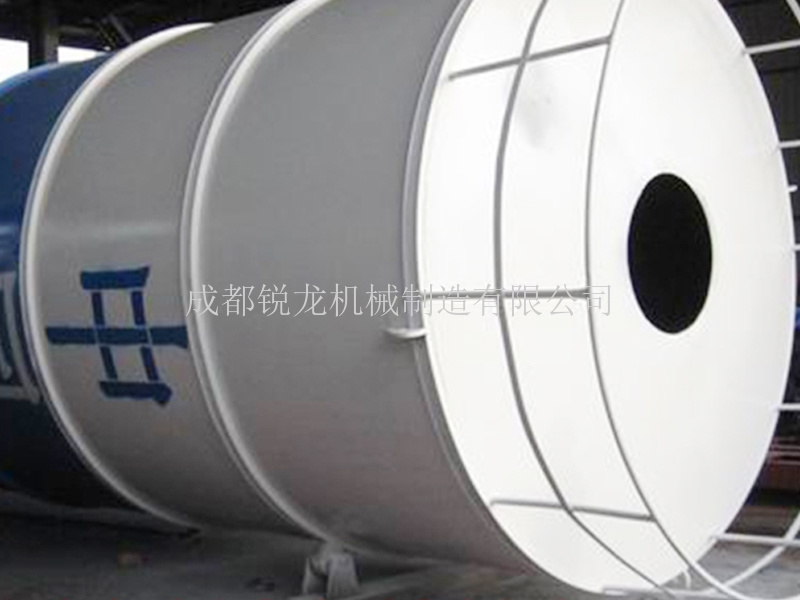

Installation of reaction frame The shield reaction frame is composed of steel ring, back shield frame and steel support. The reverse force during forward tunneling of the shield is transmitted to the bottom plate and top plate of the main structure through the reaction frame. The shield reaction frame shall be perpendicular to the bracket, that is, perpendicular to the posture of the shield machine.

Track laying: before the shield machine trolley enters the tunnel at the starting stage, lay temporary track for the battery car and trolley.

Downhole, assembly and commissioning of shield machine

The shield machine consists of a main body and a rear supporting system. The main body consists of 4 pieces of cutter head, precursor, middle body and shield tail. The rear supporting equipment consists of connecting bridge, segment erector, screw machine, 1# trailer, 2# trailer, 3# trailer, 4# trailer and 5# trailer. The main equipment is large and heavy, and a 250t crawler crane is required to be used as the main body of the shield machine for hoisting. The operation sequence is to hoist the trailer, connecting bridge and other supporting equipment into the well first, and then hoist the middle body, precursor, shield tail (erector, screw machine) and cutter head into the well in turn.

Commissioning of shield machine

Shield machine debugging is divided into no-load debugging and load debugging. ① No-load commissioning: After the shield machine is assembled and connected, no-load commissioning can be carried out. The no-load commissioning is mainly to check whether the equipment is operating normally. The main debugging contents are: hydraulic system, lubrication system, cooling system, power distribution system, variable speed system, segment erector and various instruments. ② Load debugging; usually, the trial excavation time is the load debugging of the equipment, and strict technical and management measures will be taken to ensure the safety, quality and line accuracy of the project.

Previous: None

Next page: None

Online inquiry

Products

WeChat Sweep

Focus on us

Copyright©Chengdu Ruilong Machinery Manufacturing Co., Ltd.

Website:300.cn

SAF Coolest v1.3 设置面板 ZWGSD-ZXRG-HDZVE-ZEA

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page